Centre for Rehabilitation Research and Development

Mobility technologies

Mobility technology research

Mobility is essential for health, quality of life, productivity, and independent community access. While many Canadians may take their “mobility abilities” for granted, a growing number of people must overcome mobility problems. According to Statistics Canada, disabilities related to mobility affect the greatest number of adults – approximately 2.5 million Canadians (10.5% of the population).

On a global scale, over 90 million people in North America and Europe have a mobility disability. The number of people with mobility problems is increasing as our population ages.

Our research on mobility technologies covers a broad scope, from prosthetic and orthotic devices to wheelchair systems to novel technologies for assessing mobility status. This section describes various initiatives to improve mobility for people with physical disabilities.

Powered hip for people with full leg amputations

Hip disarticulation (HD) amputation involves removal of the entire lower limb and hip joint, adversely affecting mobility and quality of life. Depending on their physical condition and life goals, some people use a prosthesis to regain mobility. However, current hip-knee-ankle-foot prostheses (i.e., mechanical hip, knee, and foot) require more energy and physical fitness to use, and therefore are rejected by many potential users.

To advance prosthetics for people with HD amputation, our research group has developed the world’s first powered hip joint that is fully integrated into a hip-knee-ankle-foot prosthesis. This new Power Hip is a combination of novel engineering design and robotics, taking data from wearable sensors into our microprocessor-control system to make the motor move the leg appropriately. This enables safe and more natural walking, sitting, and standing, while using less energy.

With our industry partner (Össur) we are in the process of translating this life-changing technology from the lab to the community, with a next generation Power Hip prototype in development.

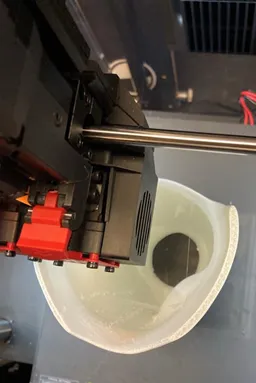

3D printed prosthetic socket insert

Lower limb amputees commonly require a new or modified socket 3 to 5 times within the first year after amputation since their residual limb continues to change in shape and size. Since delivering a new socket requires about a week from an experienced prosthetist, this process is essential but both time and cost ineffective.

To address this need, a new digital workflow was developed to create a new 3D Printed insert that conforms to the person’s new limb shape on the inside but also confirms to the old socket on the outside. Therefore, the new 3D Printed insert can be placed into the old socket to provide a good prosthetic fit without needing to create a whole new socket.

Engineering design work and mechanical testing verified that the insert is safe to use and efficient to design and manufacture, Clinical prosthetic work ensures that the new shapes are optimal for the person and that the process is time and cost effective. This research is in the process of being integrated into standard prosthetics care.

Temporary transtibial prosthesis

Before receiving a prosthesis, people often rely solely on wheelchairs or crutches for mobility during the initial months after their amputation. A simple-to-use, temporary training prosthesis could enable individuals with transtibial amputation to start learning to walk with a prosthesis and to remain active while awaiting their first prosthesis.

To meet this need, a new Temporary Transtibial Prosthesis was developed by Hossein Gholizadeh and our group. This novel device can be easily adjusted to the person by rehab staff, support the person in a similar manner to their upcoming prosthesis, allow for full knee movement, and let the person get used to standing and walking on a prosthetic foot.

Following successful pilot testing, the new Temporary Transtibial Prosthesis is entering the initial test phase for inpatients at TOHRC. This new device may not only help the person with the new amputation adapt to their new situation but also help to reduce joint issues that occur during periods of inactivity.

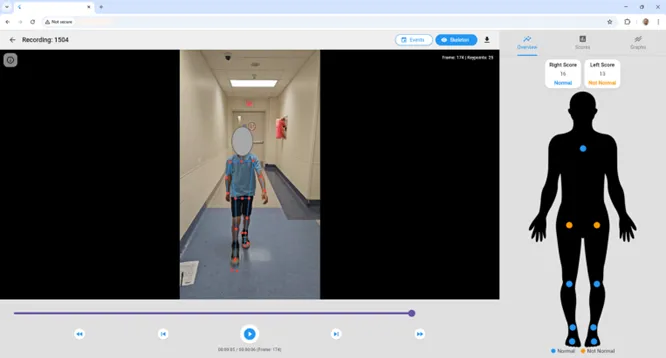

Smart hallway

For physical rehabilitation, measuring how a person moves can help clinicians understand their mobility status and make informed clinical decisions. However, measuring walking performance usually requires a dedicated gait lab or excessive time to install and use wearable sensor systems.

To bring movement measurement to the point of patient contact, we developed the 3D Smart Hallway system to allow movement capture that integrates into typical clinic schedules. The Smart Hallway system has 4 digital cameras in an optimal position at the ceiling of a hallway (i.e., good space for patient to walk that is nearby), an AI-enhanced computer to collect and process video, use Ai-based pose detection to detect the person’s joints from the digital video, a cloud system to generate 3D outcome measures automatically from the video, and a reporting option to view the results.

All the clinician needs is our smartphone app to start and stop the recording as the patient walks through the movement capture area. With partners at the University Rehabilitation Institute in Slovenia and Children’s Hospital of Eastern Ontario, we are advancing this new technology and ensuring that the best possible analyses are provides for both adults and children.

Movealytics Motion Lab

Smartphones, cloud computing, and AI are technologies that are changing how we live and work. In collaboration with uOttawa and the Children’s Hospital of Eastern Ontario, our group has combined these technologies to produce a new approach for enhancing observational movement analysis and removing distance from the clinic as an obstacle. The Movealytics Motion Lab system includes our intelligent app for collecting good quality video clips of the child or adult walking or performing upper limb movements.

These videos and phone sensor data are securely transferred to our cloud computing software for AI-based pose detection to identify a person’s joints and limbs in each frame, data processing, and automatic generation of relevant outcome measures. A new results visualization app can be accessed securely by the clinician to help interpret the results and assist with clinical decision-making. After successful initial tests, the end-to-end workflow is entering second phase evaluations before making the translation to regular use outside our research group.

Surrogate leg

To properly perform mechanical tests of lower limb orthoses, the brace must be on the leg. This is a problem when we need to perform destructive mechanical tests or cyclic tests of 1-2 million cycles. To solve this issue a novel surrogate lower limb was developed that can “wear” an ankle-foot orthosis and have similar movement biomechanics as a natural leg.

The successful design uses 3D Printing and common parts to enable the surrogate leg to be built by anyone who needs to evaluate new assistive devices. All the information to build and use the novel surrogate leg is available in an open access repository. Mechanical testing of these orthotic devices will provide information to clinicians to help with device prescription and also to industry to improve devices that are currently on the market.